Submitted by Philip Himanka

In March 2016, a miniature horse gelding named “Prince” was diagnosed by Colorado State University veterinarians with right coxofemoral joint luxation (dislocation of the femur head from the hip socket, disrupting the joint capsule and supporting structures). As a result, a femoral head ostectomy was successfully performed just a few weeks later. However, Prince was left with a significant height imbalance in his hind end.

To compensate for the limb’s height difference, as well as to balance the hip (and therefore his gait), Prince was prescribed an elevated right hind shoe. Prince’s regular veterinarian, Christy L. Downey, DVM, of Quality Equine Veterinary Services contacted me to see how we might develop a prosthetic to fashion an elevated hoof platform for Prince.

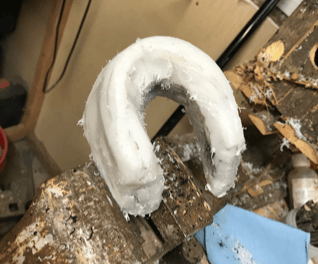

I began by using Equi-thane Super Fast™ Adhesive (Vettec™) to add layers to the edge of the hoof wall, and subsequently shaping it with the rasp or buffy. After progressive additions, we were able to comfortably sculpt the hoof angle, shape, breakover, and height.

Over time, we were able to successfully achieve a working hoof prosthetic, but we continued to refine our prototype with each hurdle we encountered. Dr. Downey brilliantly conceptualized a template that we could tape over the hoof and fill in with the Super Fast™ material. We then used dental impression material (DIM) so that Prince would have a softer weight-bearing surface in the frog area.

The next obstacle we encountered was a case of thrush. To address this, we applied a custom anti-fungal/anti-bacterial concoction underneath the DIM at the sole surface and frog that included Artimud antifungal hoof clay (Red Horse Products, Ltd), copper sulfate, and Vettec Equi-Pack CS.

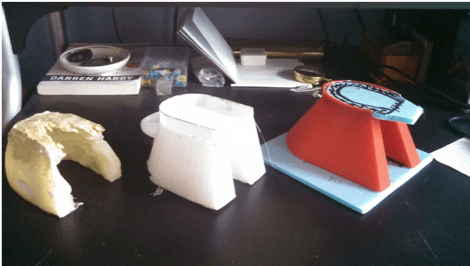

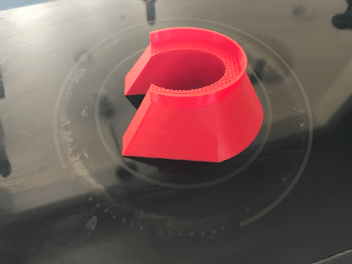

After a year of regular trims and re-application of the prosthetic, I consulted further with Anna McNeill, who works for Hanger Clinic, a company specializing in human prosthetics. She and her gifted colleagues were able to create a 3D printed model of the initial prosthetic I had built using Super Fast glue and DIM (Figure 3. Prosthetic series). My original hand-crafted prosthetic had already been used for a trimming cycle (six weeks) and worked well for Prince’s gait and comfort. The material of the 3D printed model was light and fit well on Prince’s hoof, but unfortunately, the matrix shattered under the pressure of his weight.

Despite failing the “pressure test,” this original 3D model served as a stepping stone template for the next version printed with a new compressed plastic material used for human prosthetics.

It’s now been three years since Prince’s initial diagnosis and treatment, and the results are impressive:

- Prince is sound, walks and trots with ease, and appears comfortable even on hard surfaces.

- The hoof capsule shows minimal distortions, and we continue to work towards expanding his heels with each trim.

- Prince has not developed thrush regardless of the season or presence of ground moisture.

The maintenance process that we have developed includes the following:

- I use a mechanical saw to trim along the edge between the prosthetic and hoof. The prosthetic separates from the hoof along with the DIM packing material.

- I trim, buffy, and prep the hoof for the next prosthetic to adhere to the hoof with Super Fast glue. (Using this process helps preserve the prosthetic, allowing re-use of the extension for up to three consecutive trims if not too worn).

- I attach the prosthetic to the hoof wall with Super Fast glue, leaving the sole and frog area clear to be supported by the softer material (DIM).

- Before filling with DIM or Equi-Pak™ Hoof Packing (Vettec), I apply copper sulfate or Artimud antifungal hoof clay (Red Horse Products, Ltd) to the sole and frog.

- Finally, I add the finishing touches to the hoof with the buffy.

Following these steps, each trim cycle has progressively become more efficient. More importantly, throughout the process – now going on 3 years – Prince has experienced healthy hoof growth, nice exfoliation, and no thrush. It has been heartwarming and exceptionally rewarding to work with this fantastic, caring team of equine professionals, including Prince’s owner, Stacey DeSanti.