Some relationships just work. When I first met Curtis Burns, he would not let me in the door because we were competitors in the same space. After some conversation, we both agreed we had a great deal in common and have been great friends and partners on many projects since. We are able to share ideas, failures, testing and just enjoy bouncing concepts off each other.

There are many gifted farriers in the world, but I group Curtis up in the top with a select few. Curtis is on the board of the AAPF, has shod multiple Breeders Cup Winners including Mucho Macho Man in addition to many top sport horses. He has an incredible mold shop where idea-to-prototype is sometimes only separated by hours. In addition, he is a gifted teacher and is generous passing on information to help others.

Curtis and I talk multiple times weekly about designs, materials, manufacturing, horses, adhesives and business challenges. It's been a great partnership and friendship. The partnership has made both of our jobs more fun.

I approached Curtis earlier this year with a challenge. I wanted his help making the equine industry premium medical boot. The boot used in the big teaching vet clinics, the boot used when only the best will do. I told Curtis that I would make the boot and challenged Curtis with the pad. Curtis called me the next day excited. Curtis not only had an idea but had already molded a prototype.

The idea was not only simple, but I immediately said "that will not only work, we need to start on it yesterday." The concept is simple yet brilliant.

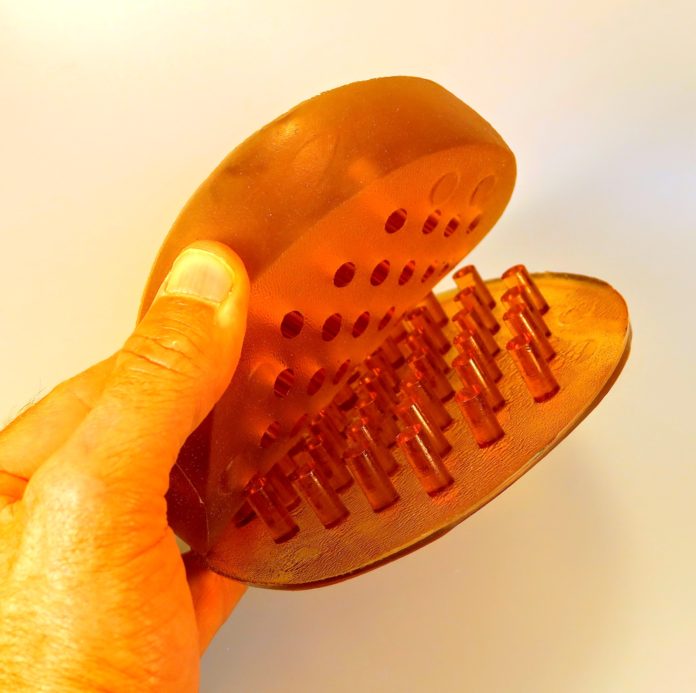

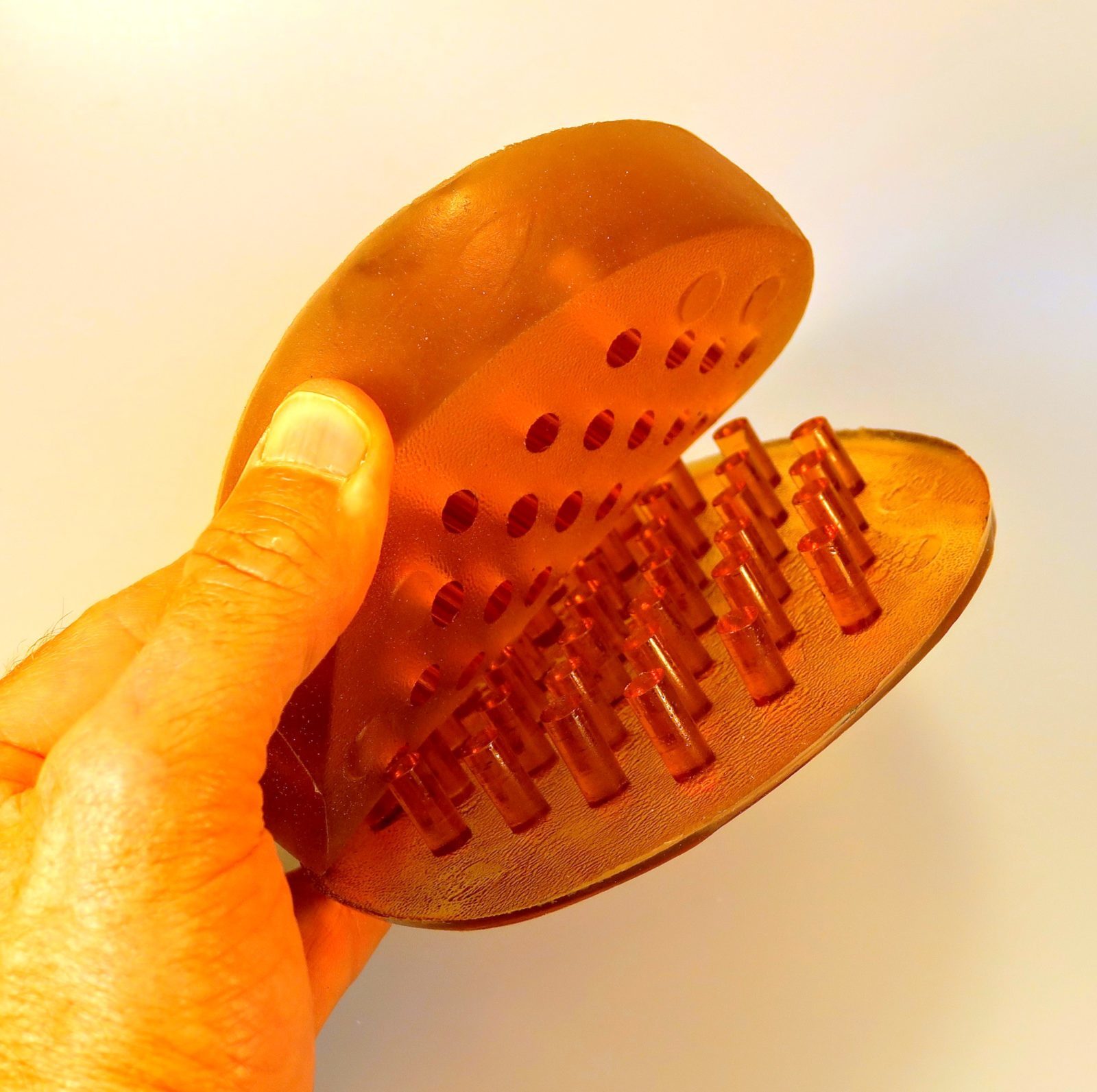

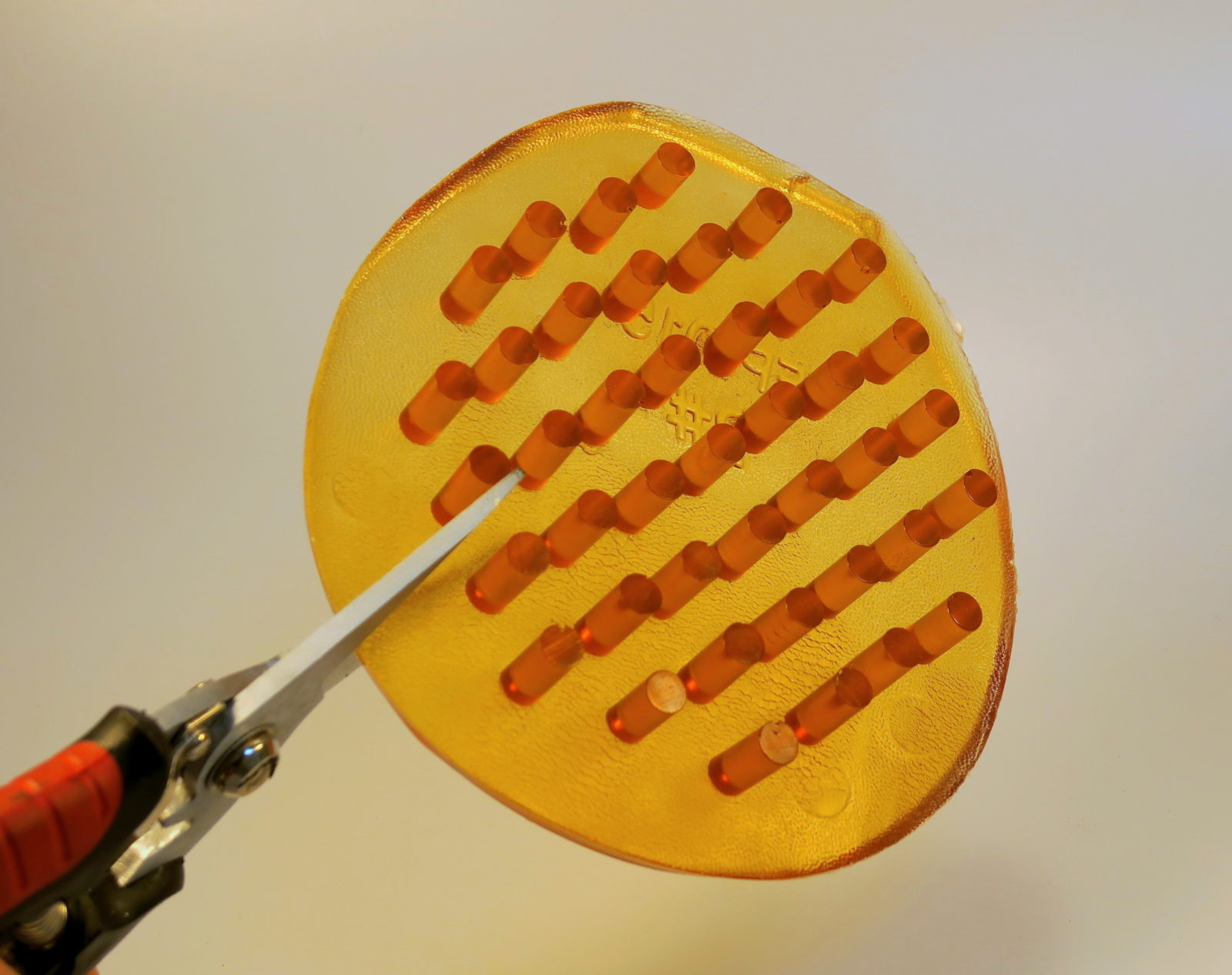

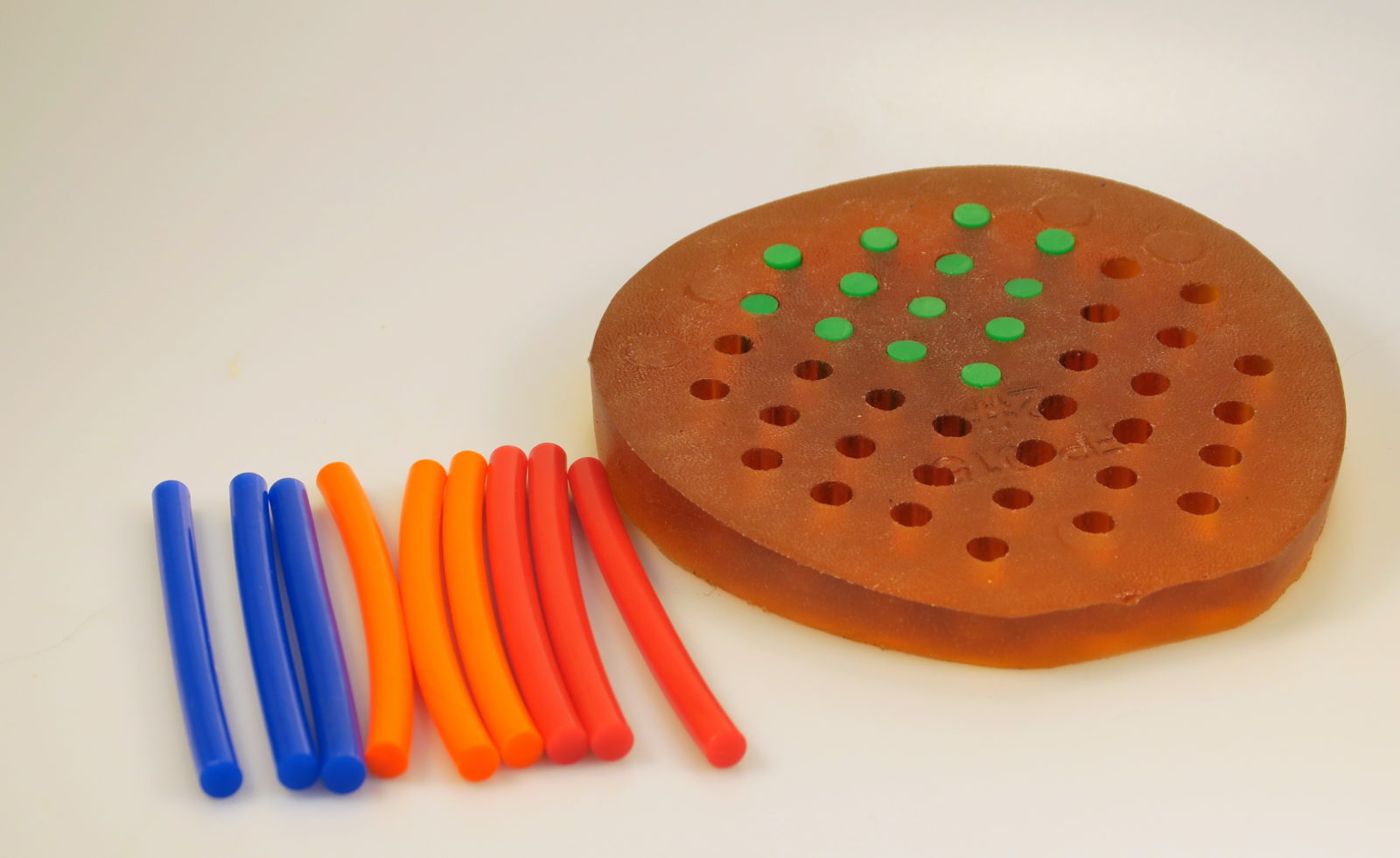

1. The pad would be molded in a flexible medium that had cylinders molded on the base. The cylinders would both reduce weight and accept rods of different densities.

2. To adjust the pressure and density in different areas of the pad, rods of different density could be inserted in different regions of the pad.

3. The rods could be stand alone or in fixed together on a plate. If fixed on a plate, different regions can be cut away and/or inserted into the pad.

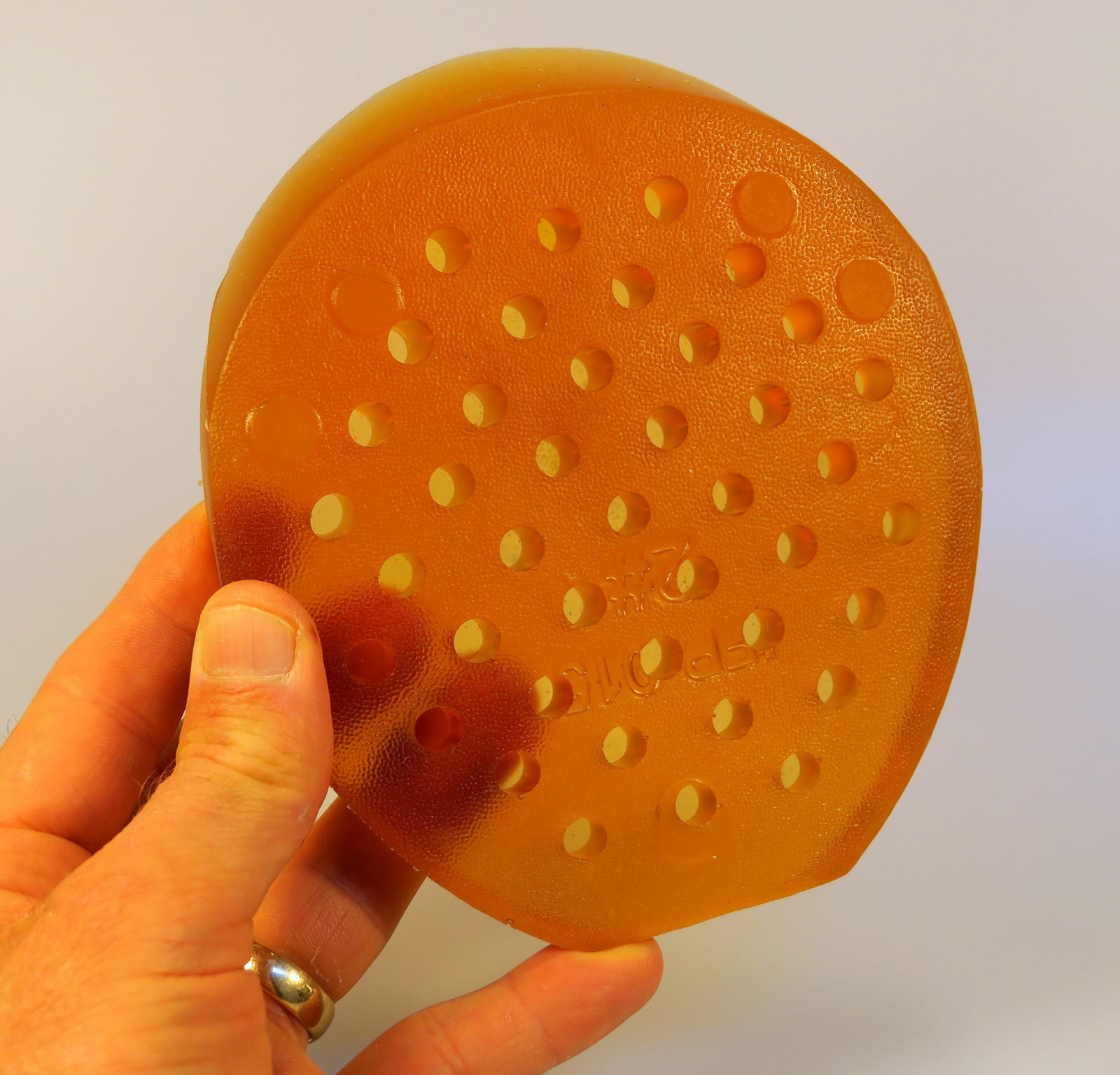

Simple but brilliant. Pad has holes in the base that don't go all the way through the pad.

The holes are designed to accept rods in different densities.

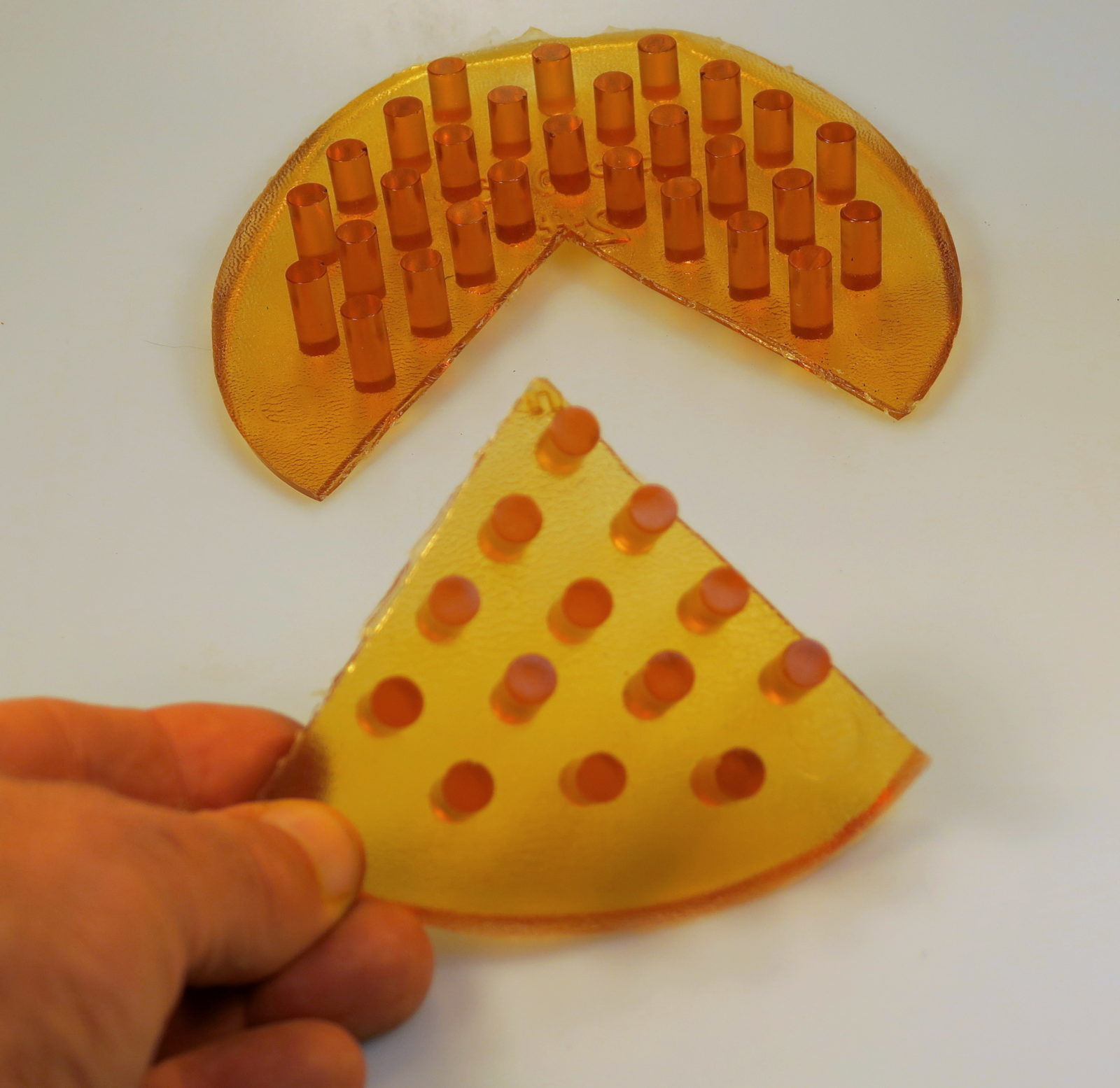

Different regions of the plate could be removed.

For example, the frog region could be cut out and inserted in the pad to apply more frog pressure.

Frog area inserted. The frog area will now be more firm.

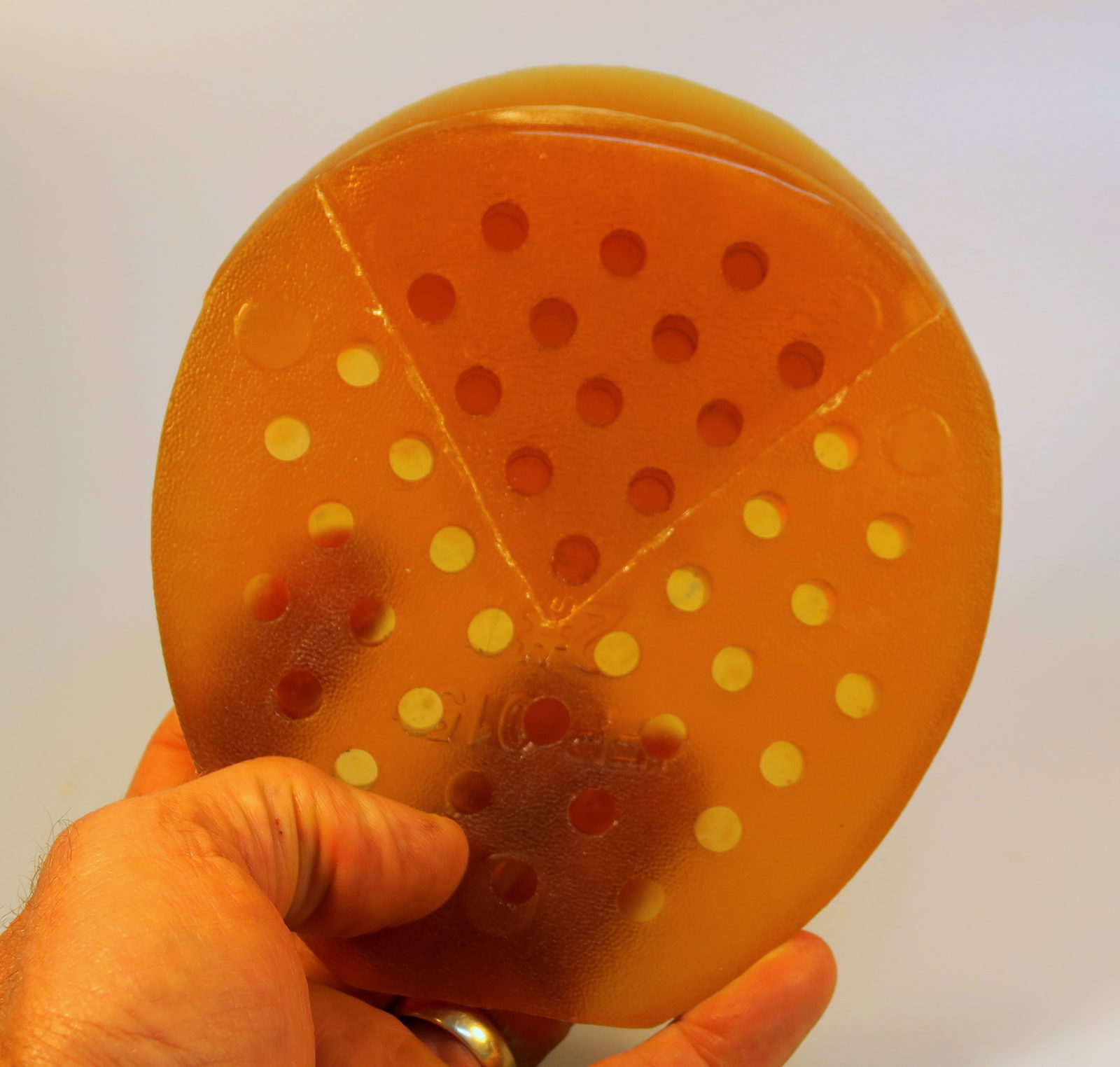

Holes go down. Hoof stands on the flat side with no holes. Holes do not come through the pad.

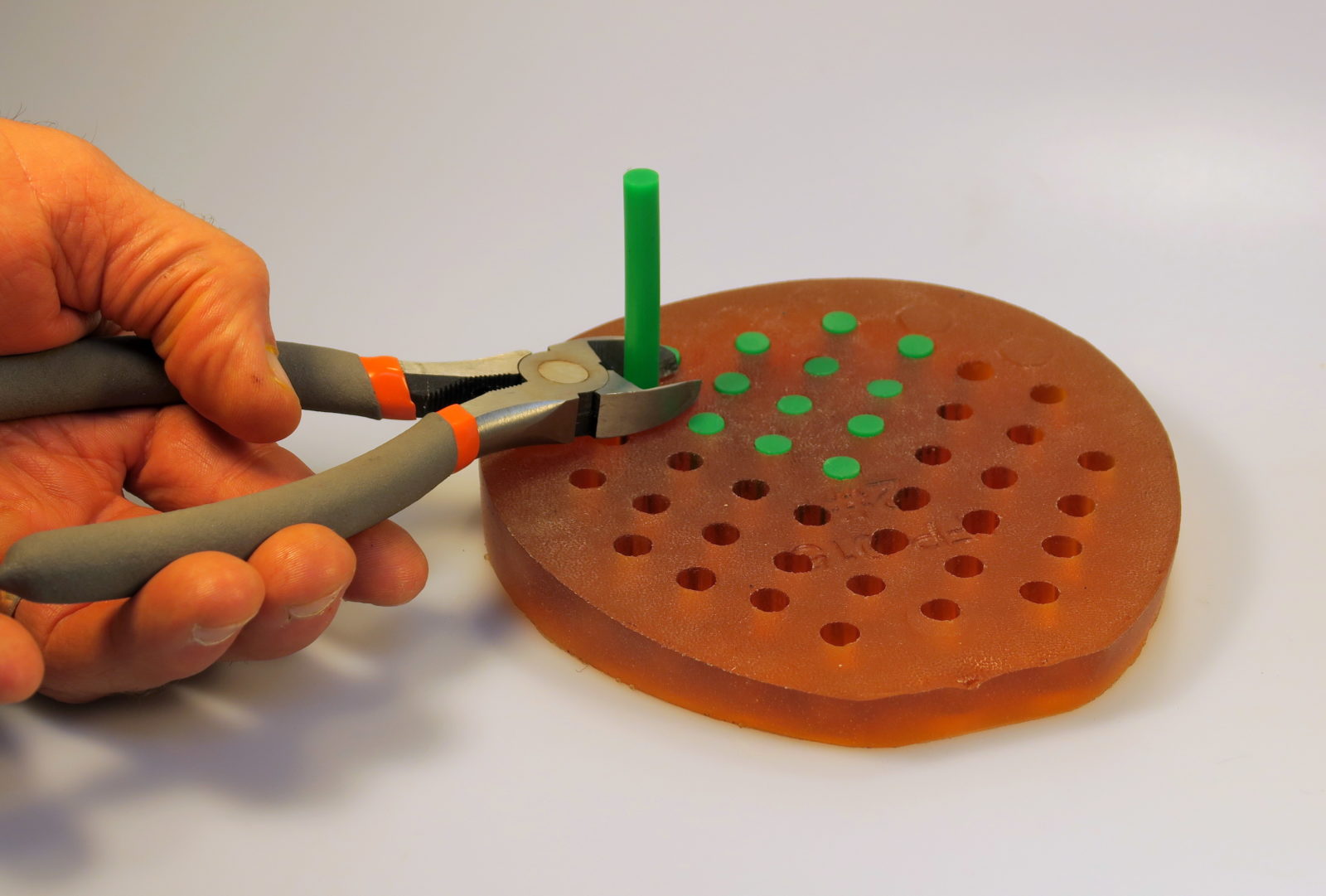

Another idea is to have rods in different densities: firm, medium and soft. Insert rods of different densities in different regions of the pad a cut off. Change and test until horse is comfortable.

Rod examples in different densities. Easy to apply and adjust.

With the pad showing great promise, I have been working on boot designs that will compliment the pad. We are looking for a very long wearing, high quality materials, stays in place and does not twist. A unique "Heel Sling" design is working very well. The heel sling hugs the heel bulbs keep the boot in place and without twisting.

One of the potential prototypes. High quality leather and a patent pending "Heel Sling".

One of the boot designs has a "Heel Sling" that runs between two layers of fabric. The fabric has been cut away to show how it works. The sling snugs around the heel bulbs preventing boot loss and twisting.

Another potential design. High abrasion fabric with a front snug strap.

Slip the pad in a newly designed premium Easyboot Cloud Rx!

Curtis and I are excited about the possibilities and will continue to push these products to market. We both believe they have a place and will help horses. We will keep you posted and plan to seek out help with testing.

Let us know if you have interest in helping us test the concept.

Garrett Ford

President & CEO

I have been President and CEO of EasyCare since 1993. My first area of focus for the company is in product development, and my goal is to design the perfect hoof boot for the barefoot horse.