I may not be a farrier, but that doesn't keep me from learning about hooves and looking at them.

Everyone who has Googled "laminae" (it’s what makes Friday nights so exciting now that we’re not out clubbing and staying up until all hours on the weekends) will have read that it’s “like Velcro”. It’s the grip between the sensitive bits and the insensitive bits. Sensitive bits are on the coffin bone, insensitive bits are on the hoofwall. They lock together unless your horse gets laminitis… and that’s about all we can conceptualize.

But how does the hoof grow “down” and the sole not fall off? How does it grow “down” past a coffin bone like some sort of demented sock? (If I tried pulling it off your foot, by the toe, it would just keep fabricating at your ankle and never come off. I could make it 10 feet away and that sock would still be at ankle height. TRIPPY.)

(Do NOT study hooves while using LSD. I haven’t done it… but I’m going to go out on a limb and say it would be the stuff of nightmares.)

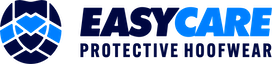

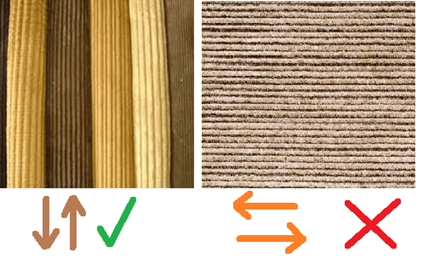

To answer this question, let’s look at my least favorite fabric of all time: CORDUROY.

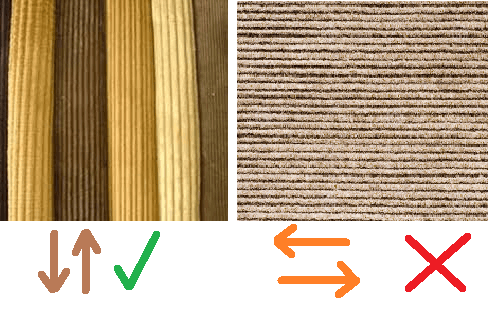

Fashionable: Apparently Logical: NO

Naturally, when designing clothes, the inclination is to create long, lean lines, by running your corduroy fabric north-south, in vertical lines. Nothing is more slimming than the sound of my legs rubbing together in corduroy pants; like a human-sized cicada bug. In fact, I’m pretty sure the cave man discovered fire, because he had attempted to run in corduroy pants and created a blaze from the ensuing friction.

If they could only see the practicality of sewing corduroy in horizontal lines, then the fabric would slide against each other WITH the grain of the grooves. My thighs might LOOK wider in horizontal lines, but at least I wouldn’t sound like a bullfrog in mating season when walking across my living room.

Say no to fashion and yes to quiet legs!

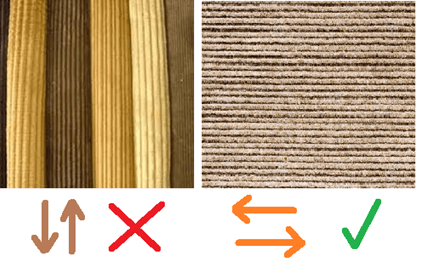

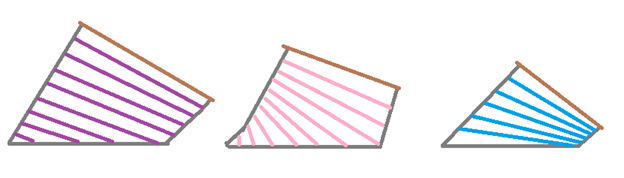

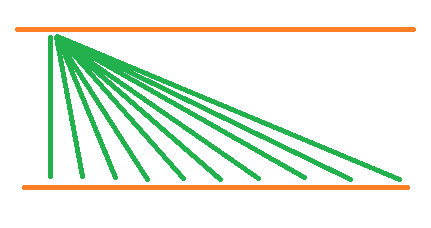

That’s my smooth segue back to laminae: they groove from insensitive laminae to sensitive laminae like drawer slides.

- Hoofwall

- Insensitive Laminae

- Sensitive Laminae

- Coffin Bone

I should’ve drawn the coffin bone with a 5-degree angle or so. I’m drawing-limited when I use my mouse. The salient point is: the coffin bone has sprouted its Velcro and the hoofwall has its Velcro. Unlike Velcro, that has 50 million hooks and loops in all directions, we have more of a drawer slide system. Yes, the top rail (insensitive laminae) is locked onto the bottom rail (sensitive laminae) and allows the growing hoof wall to “slide” down the coffin bone and shed out/off the bottom. Or like properly-thought-out corduroy: it can slide in the direction that nature intends; going with the grain.

It doesn't work on pants, but it DOES work on laminae.

Won’t the hoof just slide off then?!?

Have you ever installed tongue and groove flooring? Have you ever snapped the next piece of wood into place and then realized it needed to “skootch” 1/8” to the left? Heaven and Earth can’t get it to move. You can “tap” it with a mallet and quickly find that you need a lot more force than a tap to get it to slide. Why? Because you generally have a groove that’s 6 feet long and there is a lot of friction and resistance to sliding.

Lucky for you, your horse’s hoof is a lot like stubborn flooring. It’s not going to slide down and off without a lot of growth and pushing.

In knowing that the hoof is a conveyor-belt moving “down”, you have to consider what can stop the conveyor belt or, worse yet, cause it to “back up” at the production from the hairline.

Let's look at the flop of the hoof tubules and the spacing of the growth rings: what can we tell?

While they look like awesome elf socks, they are three patterns of growth rings: even growth, heel-faster-than-toe, toe-faster-than-heel.

You know when you fall asleep on the couch and you wake up with your arm paralyzed? It’s a painful lesson in blood flow as your arm prickles back to life. What we learn is: you can angle something in such a way that the blood flow will lessen or cut off entirely.

I’m not saying your hoof has to be shaped into a certain degree of angle to be healthy, but if your horse is growing lopsided rings: something is out of whack.

Heels growing faster than toes show no toe growth: not good.

Toes growing faster than heels show slow heel growth: not good.

It’s visibly like gathering, in sewing, to me. You have one side bunched and the other out-doing itself in length.

You, as the owner, can look at your growth rings and start the conversation with your farrier. I trim my own horses, so it’s a lot of awkward conversations with myself…most of the time yelling, “WHAT ARE YOU DOING?!”

You can have issues with growth coming in, or lack thereof. The uneven growth pattern of a toe vs a heel. But what happens when your drawer slides start backing up? What if all the growth wants to come in, but what is touching the ground is “in the way”? You can get “pushed-up” sections of hoof.

Let’s say I trimmed my horse and I left a lump on the hoofwall. I just didn’t notice. Now, she may or may not wear it off. If she’s got any sort of shoe or boot on and it’s not wearing, then she effectively has a lump in her “shoe” and the effect will be the drawer slide pushing back against the new growth.

You’ll see the ripple in the hoof wall. Like a stone thrown in a lake, you can see the pattern of movement by looking at ripples.

Now, as I wrote in the Polishing a Turd blog, sometimes we’re holding on, when we should be letting go. There is probably a bathing suit crammed into the back of a drawer that is waiting for me to let ‘er go too. In hooves, they want to abrade, crack, split and fall off. They want to grow (so that there is hoof at all) only to be worn. When they don’t get worn as fast as they are growing, they speed up the breaking process and flare, crack and split off.

"Tootles! Ta ta! See ya later!"

That horse is going to run into trouble when we keep the hoof from breaking.

You heard me right.

Keep. The. Hoof. From. Breaking.

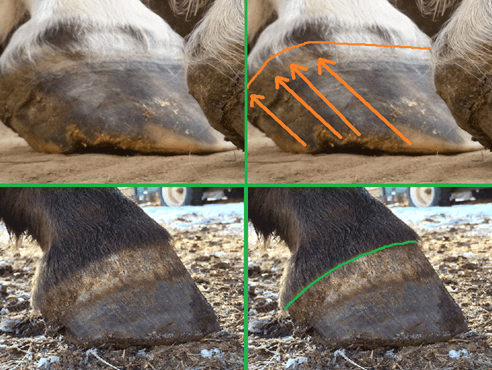

The heel can flare out and the quarters go wide. The bars flop over. Looking at Cinder’s hoof after Winter:

It’s wider than long: 125mm x 115mm

Anatomically, she’s not wider than long, she just happens to have worn off the surplus toe growth and didn’t wear off the heel growth over winter. You can see a nice tight connection of sole to hoofwall at the toe, but overgrowth at the quarters and heels. When that surplus is trimmed down, she is then 115 by 115, a “round” hoof.

The problem she *could* have is, if I left that heel on and then bound it in such a way that it wasn’t allowed to flare… well then I would be pushing back on her drawer slides, wouldn’t I?

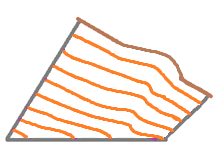

Look at her top hairline here. Looks even and sloping towards the heel. But when we looked at the sole, we saw how she was managing to do that: the drawer slides were pushing down and flaring OUT. If that heel area is not going to wear, it still has to get out of the way. We have a hint of the flare by looking at her hoof tubules and see that they are folding as we get closer to the heel.

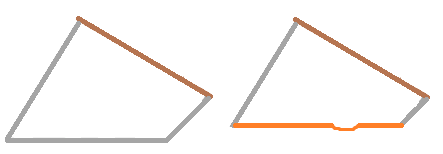

We all know that the shortest distance between two points is a straight line:

But we can also illustrate that, the steeper the angle, the longer our line can get away with being. Our up and down line is 43mm, and they sneakily get longer such as the increasing slopes being 45mm, 50mm, 55mm, 58mm, 65mm, etc. until we reach the final line which is 110mm long! The good part is, the hoof “drawer slides” are having no push back. The bad part is, that flare is REDONKULOUS and is playing havoc with the other team players in the hoof: namely the laminae.

Your laminae is like a make-up brush. If it’s short bristled, you have great control and connection. The makeup goes exactly where you want it to and will look great for hours.

The longer the bristle, the less control and connection you have with your brush. It’s going to start out bad and only get worse as the night goes on.

Have you ever seen a washing machine with an unbalanced load? At first it vibrates a little, then it vibrates a LOT and the shift of the load starts worsening and worsening. Your washer starts shimmying, but ends up galloping across your laundry room. Thank goodness there is a laundry room door, or it would get loose and roam your house. Here is a long hoofwall doing the washing machine shimmy.

We know that longer growth in the heels, left untrimmed, starts to flare them out. But what if you put shoes on them and tie those heels into position? Urethane or metal, if you keep that flare in, it’s like putting a corset on your hoof.

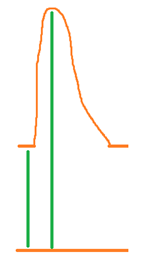

You gather in that heel flare and since it can’t go “out” to the side, it only has one place it can go: bolstered upright and spilling out of the top. Remember our lines? We started with a 44mm line and let it slope out to a 110mm line. If you grabbed that line and shoved it back into being upright, you would have this:

When I take a pushed up coronet band and compare it to Cinder’s hoof, you can see the natural hairline slope and how much more pushed up our top guy is. Horses do a lot of forward thrust and not a lot of spinning and brake-slamming. The toe gets nice abrasion and the quarters and heels don’t. Then you add a shoe (urethane or metal. In this instance it’s anything that will hold that heel in place and prevent it from –GASP- flaring. Heaven Forbid!) and you get the drawer slide backing up the hoof wall and pushing up the hairline, like a lovely bosom in a corset.

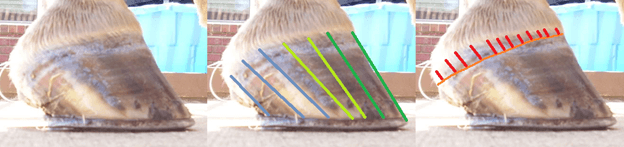

Here again, we’re going to see an example of the hairline being pushed back and up, because the heels are long and cannot flare out, so naturally, they must push back on their slides. The more vertical lines are dark green. The light green start to show divergence from uniformity, they are starting to bend further away from the parallel: they are longer and looking to escape pressure. They need to fold to “be longer” and stay in pace with the rest of the hoof. The further back the hoof goes, it naturally is shorter near the heel. In the case that the heels are long, they have to go somewhere, they will start bending even further off the parallel. I drew in the “Cinder line” on the right photo. Not only did the horse have the highest push-up in the back portion of the hairline, it was ALSO compensating by letting the hoof tubules fall farther out of parallel with the rest of the growth.

In two ways he’s saying: THIS IS TOO LONG.

Hoof tubules bending to allow more room while being long? CHECK.

Shoe keeping hoof from flaring so it has no choice by to push back up at the origin at the hairline? CHECK.

As an owner, take some time to read your hooves. You might not trim, but you have eyes! Pick up the feet and look for what the horse is trying to get rid of: sole that goes chalky and flakes out with just a hoofpick? You think your arm strength and that tiny piece of metal can flake out sole when your 800lb+ horse, romping around is somehow unable to? Hint: it must not be touching the ground or touching anything or it would’ve fallen out on its own. Solution: you gotta get it in contact with something. That could mean taking shoes off, trimming, adding gravel to a paddock or any number of things. All roads lead to Rome: get the hoof in contact with something that will wear it down.

Keep an eye on your flares if you are barefoot: the hoof is escaping outwards.

Keep an eye on your hairline if you are shod: the hoof is escaping upwards.

Your laminae connectivity will thank you.

Holly Jonsson

Director of Sales

Through a lifetime of "horse crazy" and the fortunate experience of riding nearly every shape and size of horse, I got to see a wide array of hoof shapes and sizes. No Hoof, No Horse is very true to me. I want to ensure that horses on every continent have a variety of footwear to pick from, to ensure the best match is found. I want your partner to be happy from the ground up!